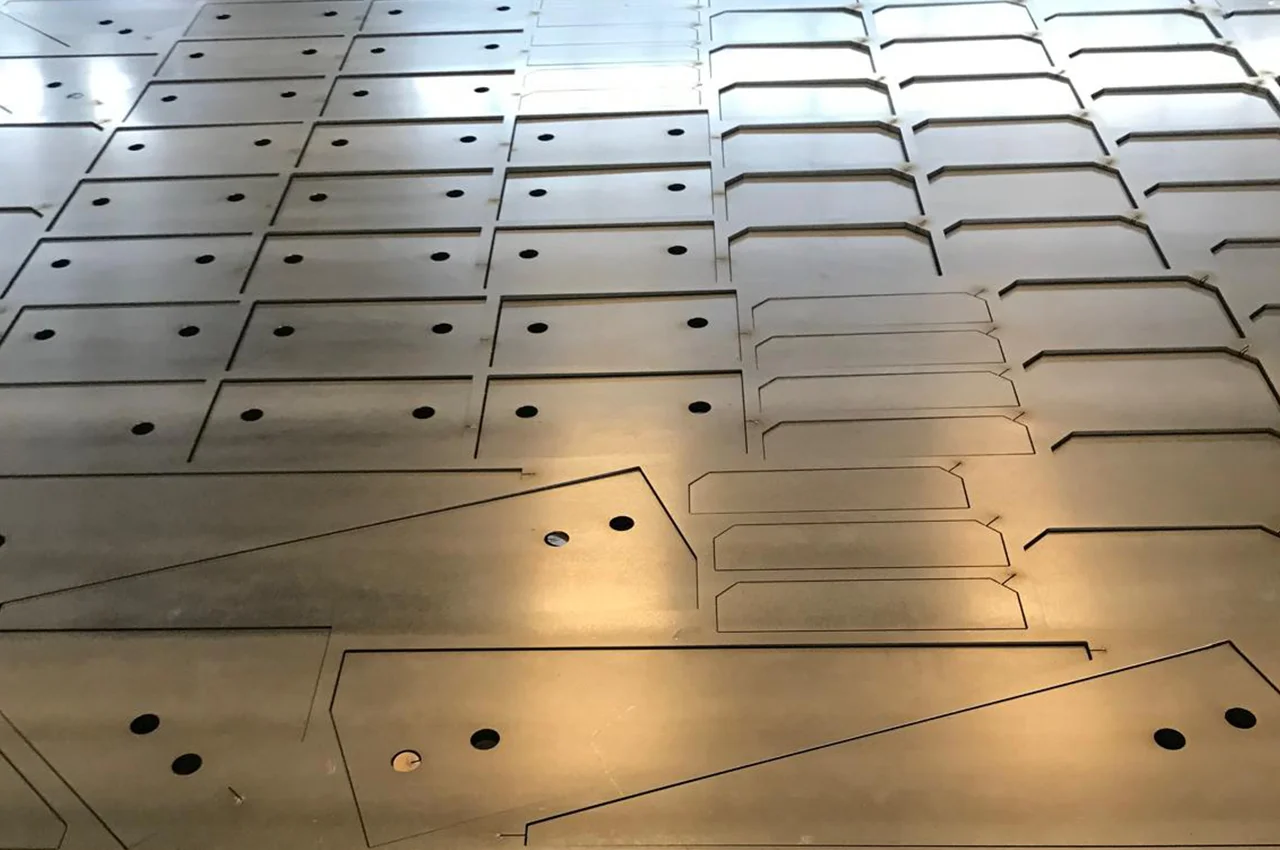

IRON AND STEEL LASER AND MECHANICAL CUTTING

Tubes, open profiles, and beams’ laser and mechanical cutting

Laser cutting is a process that melts and vaporises various materials—primarily steel and iron—producing highly customisable tubes, open profiles, and beams suitable for multiple industries, including construction, electromechanics, and automotive.

At Carboni Steel, we employ two distinct cutting technologies to manufacture our products: band saws and 3D/2D laser systems. In the first case, a blade directly cuts metal bars into segments of various sizes. Laser systems, on the other hand, further enhance performance and enable the creation of more complex geometries while keeping the material’s original properties virtually unchanged.

Based on the requirements of our customers in Italy and abroad, we select the most suitable cutting technology to execute straight or angled cuts at the desired gradient. All the technologies in our facilities deliver exceptionally precise results. Thanks to the high performance of our 3D laser systems, we can halve tolerances on lengths and spacing.

If you’d like more information about our laser cutting services, schedule an appointment with one of our specialised technicians.

MECHANICAL CUTTING SYSTEMS

3D LASER TUBE CUTTING SYSTEMS

2D LASER SHEET CUTTING SYSTEM

LT14.20 laser tube

Technical specifications

| Tubes & open profiles | Unit of measurement | Value |

| Bar minimum length for loading | mm | 3.000 |

| Bar minimum length for loading | mm | 12.500 |

| Bar minimum length for loading | kg/m | 100 |

| Maximum finished-part unload length | mm | 12.500 |

| Fiber laser source power | W | 5.000 |

| Round section | ||

| Round section size | mm | 25 – 355 |

| Square section | ||

| Square section side | mm | 25 – 260 |

| Rectangular section | ||

| Minimum side size | mm | 25 |

| Maximum side size | mm | 300 |

| Angle section (L-profiles) | ||

| Minimum leg size | mm | 40×40 |

| Maximum leg size | mm | 250×250 |

| Beams | Unit of measurement | Value |

| Bar minimum length for loading | mm | 3.000 |

| Bar maximum length for loading | mm | 12.500 |

| HEB profile maximum size | h | 260 |

| HEA profile maximum size | h | 260 |

| IPE profile maximum size | h | 300 |

| UNP profile maximum size | h | 300 |

LT8.20 laser tube

Technical specifications

| Tubes and open profiles | Unit of measurement | Value |

| Bar minimum length for loading | mm | 2.500 |

| Bar maximum length for loading | mm | 12.000 |

| Linear bar maximum weight | kg/m | 40 |

| Finished product discharge maximum length | mm | 8.500 |

| Round section | ||

| Round section size | mm | 12 – 240 |

| Square section | ||

| Square section side | mm | 12 – 200 |

| Rectangular section | ||

| Minimum side size | mm | 15 |

| Maximum side size | mm | 200 |

| Beams |

Unit of measurement |

Value |

| Bar minimum length for loading | mm | 2.500 |

| Bar maximum length for loading | mm | 12.000 |

| HEB profile maximum size | h | 140 |

| HEA profile maximum size | h | 160 |

| IPE profile maximum size | h | 200 |

| UNP profile maximum size | h | 200 |

| Finished product discharge maximum length | mm | 8.500 |

TL220 laser tube

Technical specifications

| Tubes and open profiles | Unit of measurement | Value |

| Bar minimum length for loading | mm | 2.500 |

| Bar maximum length for loading | mm | 9.500 |

| Linear bar maximum weight | kg/m | 25 |

| Finished product discharge maximum length | mm | 6.500 |

| Fiber source | W | 4.000 |

| Round section | ||

| Round section size | mm | 20 – 200 |

| Square section | ||

| Square section side | mm | 20 – 160 |

| Rectangular section | ||

| Minimum side size | mm | 20 |

| Maximum side size | mm | 160 |

PLUS 6025 sheet laser system

Technical specifications

| Unit of measurement |

Value | |

| Worktable size | mm | 2.000 x 6.000 |

| Maximum cutting thickness – Iron | mm | 50 (upon request 60) |

| Maximum cutting thickness – Stainless steel | mm | 30 (upon request 40) |

Band saw machinery

Technical specifications

| Unit of measurement |

Value | |

| Maximum section cutting capacity | mm | 1.000 x 600 |

| Maximum cutting angle | Degrees | 59 |

Additional services

Consultancy

Pre- and post-sales support to help customers choose the right products, from their design to their implementation and use.

Transport and logistics

Extensive facilities, well-organised spaces, and dedicated delivery vehicles ensure a reliable, daily, and efficient service.

CONTACT US

Request more information

To request additional details about our products or services, please fill out the form, and one of our specialists will get in touch with you.